Design For Manufacture (DfMA)

& Off-Site Manufacturing (OSM)

Intro

With a strong track record in delivering complex prefabricated MEP installations, we are the ideal partner for all your Design for Manufacture and Assembly (DfMA) and Off-Site Manufacturing (OSM) needs.

Through our trusted fabrication and assembly partners, we provide a turnkey service that encompasses everything from the early identification of potential OSM zones to the creation of fully coordinated fabrication and assembly

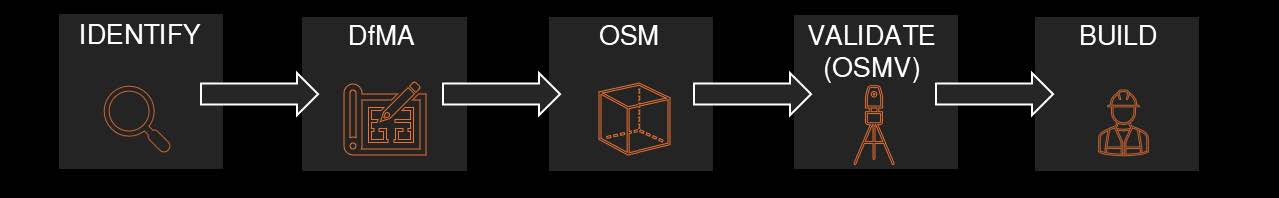

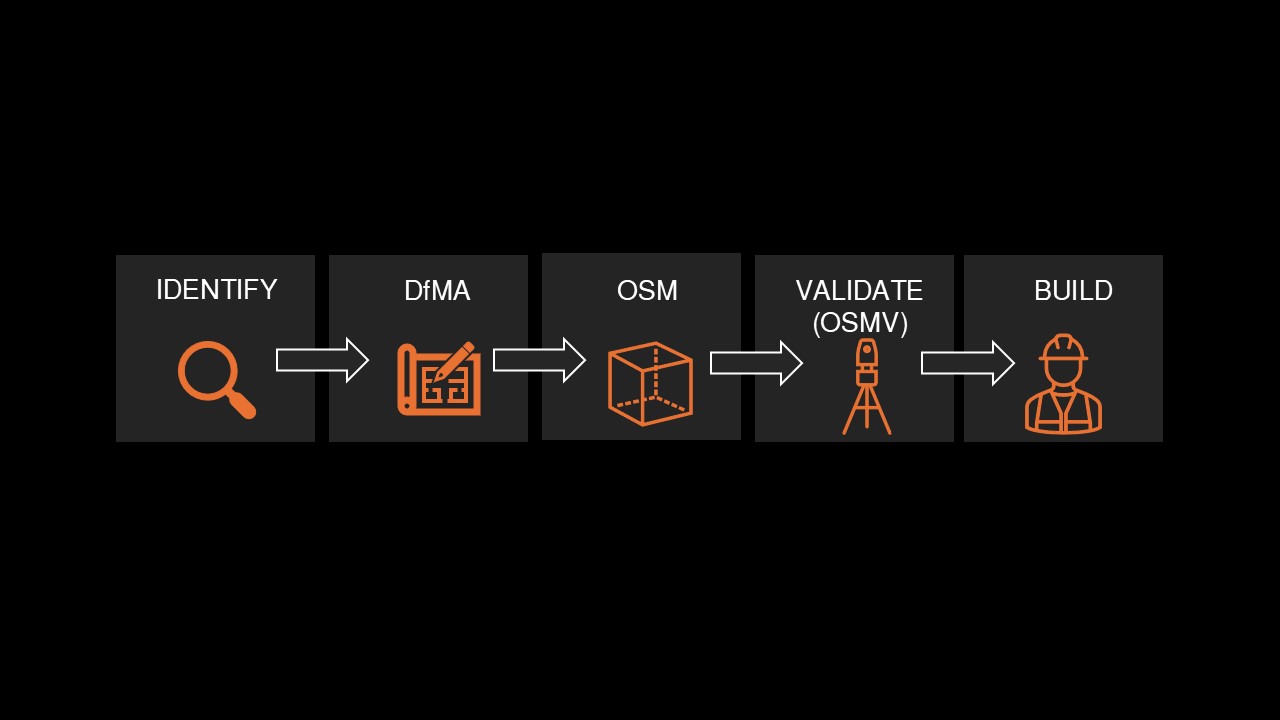

Identify

At Stages 4/5, we assist our clients in identifying areas with off-site manufacturing potential by thoroughly reviewing the Stage 3 model:

1. Corridors and risers – We prioritize generic corridors and risers that are well-suited for MEP (mechanical, electrical, and plumbing) modules.

2.Plantrooms – These often present a high ROI when adopting an OSM approach. This can involve a hybrid method, where some elements are prefabricated and assembled on-site, or a fully packaged plantroom that is pre-assembled, tested, and delivered ready for installation.

3.Energy Centers and Utility Hubs – Prefabricated energy centers, or utility hubs can be assembled off-site, tested, and delivered.

4. HVAC Ductwork – Prefabricated duct sections or entire HVAC modules can reduce installation time and ensure better quality control, especially in larger buildings like hospitals or commercial towers.

5. Modular Electrical and Data Containment – Cable trays, conduits, and pre-assembled wiring harnesses can be prefabricated and delivered as complete modules to reduce installation time and complexity.

6. Welding zones – We identify areas where welding is the specified jointing method and recommend prefabricated pipework to enhance quality control and minimize hot works on-site.

7. Restricted hot work areas – We also pinpoint locations where hot works are prohibited, offering alternative prefabrication solutions.

8. Repeating assemblies – Repetitive components, such as utility cupboards and manifolds, are prime candidates for off-site prefabrication.

DfMA

Once we have identified all areas with OSM potential, we begin coordinating these zones within the model using a DfMA (Design for Manufacture and Assembly) approach.

1. Coordination – Our DfMA–based coordination goes beyond modularized services. We also account for module framing, anchorage locations, and constructability considerations such as break flanges and field welds. These elements are carefully coordinated with non-modularized items and the building fabric to ensure seamless integration.

2. Access and Transit – At this stage, we determine the optimal sizes for OSM components by considering site access routes and identifying potential pinch points for moving modules from the set-down area to their final location. We also consider transportation methods to provide input into the most logical and efficient dimensions.

3. Sequencing – We carefully plan the installation sequence, identifying any areas or intersections where design adjustments are necessary to accommodate other services.

4. Detailing – Once coordination is complete, we move on to creating detailed fabrication and assembly drawings. This includes generating Bills of Materials and Quantities (BOM & BOQ) for procurement and commercial purposes, as well as outlining testing and QA/QC requirements.

OSM (Off Site Manufacturing)

We collaborate with trusted fabrication and assembly partners to deliver fully fabricated and assembled modular MEP solutions. Our services encompass everything from overseeing procurement to testing and delivery. Throughout each stage, we keep our clients informed with regular updates on progress, potential issues, and any delays.

Off Site Manufacture Validation (OSMV)

Our OSMV service uses advanced geospatial technology to ensure the

precision and accuracy of prefabricated components before they arrive on-site.

- Advanced Scanning: Using our in-house Leica RTC 360, we scan modules, skids, racks, and prefabricated pipework to create detailed point clouds.

- Accuracy Comparison: With Cyclone 3DR software, we compare the “as-built” point cloud to the design file, identifying any out-of- tolerance elements.

- Remedial Action Planning: Automated plans are created to address and rectify these discrepancies, ensuring that installation personnel can correct them efficiently.

- Site Passport Pack: We provide a comprehensive “Site Passport Pack” for spatial approval of modules, which can be referenced at any future stage.

Build

By using 4D BIM, which integrates time with the 3D model, we assess how prefabrication can be effectively incorporated into the construction timeline. By linking construction schedules with the BIM model, we can simulate various scenarios where prefabricated components are delivered and assembled at different stages of the project. This allows us to optimize both the delivery sequence and on-site installation process.

Benefits of 4D BIM for OSM:

• Reducing On-Site Disruptions: Prefabricated elements simplify on-site work. By aligning the delivery of OSM components with the construction schedule, we minimize material storage needs, easing space constraints and reducing potential disruptions.

• Mitigating Risk: 4D BIM enables project managers to visualize the installation process in advance, helping to identify risks or delays caused by factors such as weather conditions or site access limitations.